Cosid industrial brake linings

The Cosid brand belongs to the brake material manufacturer INNO Friction. This manufacturer specializes in producing advanced friction materials intended for industrial use. Experience in the development of innovative materials, automated mixing methods, constant quality control, and modern production processes ensure the highest level of product quality.

Friction materials, dedicated to specific applications, are developed and tested based on the extensive experience and knowledge of the INNO Friction group, relying on their own research and modern technologies.

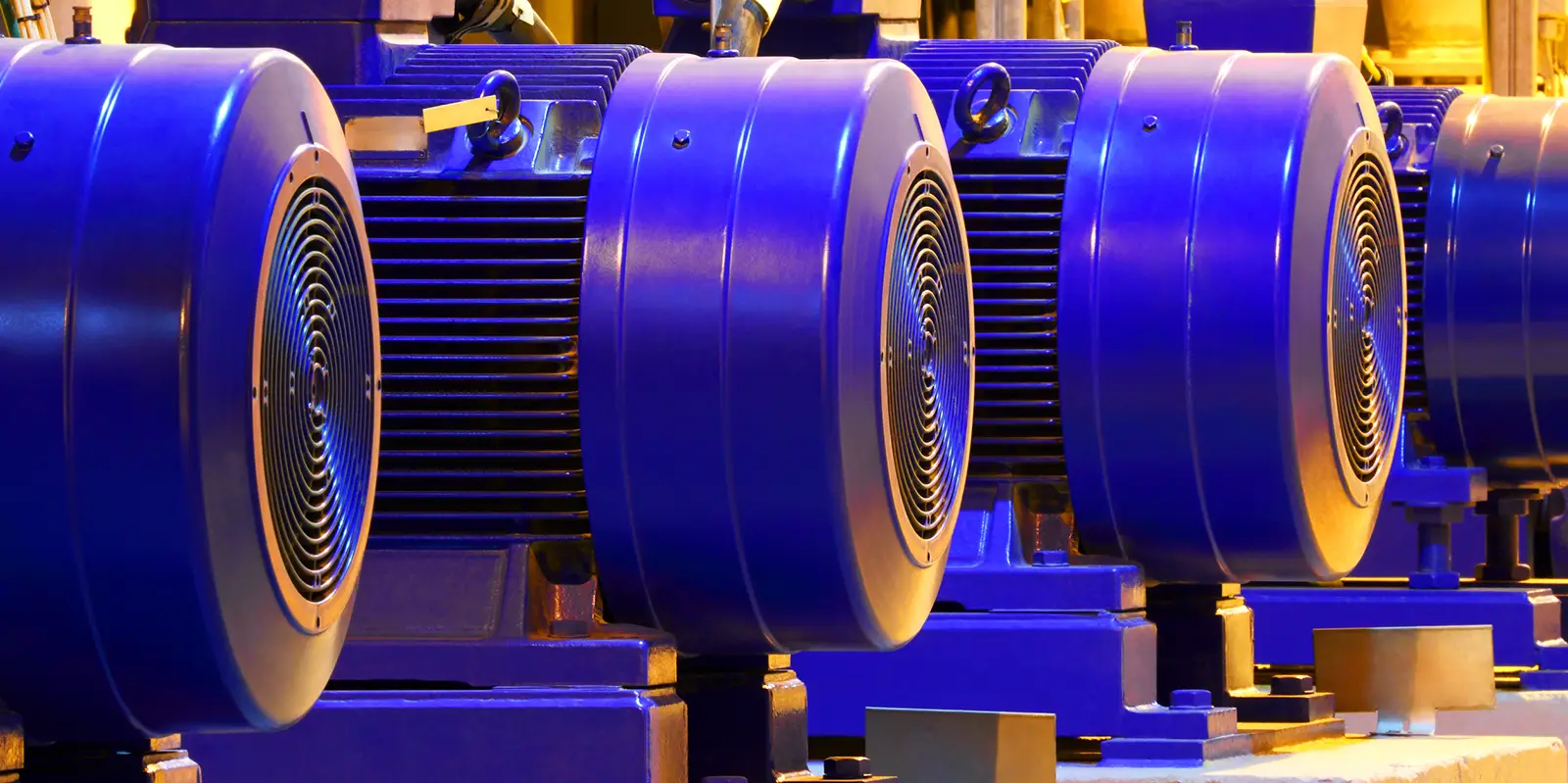

Cosid brake linings are available as:

- brake bands used in cranes, lifts, hoists, and general machinery construction

- drum brake linings used in overhead cranes, special vehicles, and general industrial applications

- brake and clutch linings used in drive technology, agricultural engineering, and machine building

- brake pads for stamping and forging presses

Production portfolio

COSID 101

COSID 101 is a flexible friction material offered as a rolled lining. The material concept is based on a rubber compound with metallic fibers. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 101 is easy to process.

Applications: static/holding brakes, band brakes, drum brake refurbishment, special applications.

Form: flexible strips wound into rolls.

COSID 107

COSID 107 is a flexible friction material offered as a rolled lining. The material concept is based on a rubber compound with metallic fibers. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 107 is easy to process.

Applications: crane brakes, engine brakes, band brakes, centrifugal clutches, oldtimer restoration.

Form: flexible strips wound into rolls.

COSID 110

COSID 110 is a flexible friction material offered as a rolled lining. The material concept is based on a rubber compound. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 110 is easy to process.

Applications: static/holding brakes, band brakes, drum brake refurbishment, special applications such as coal processing.

Form: flexible strips wound into rolls.

COSID 120

Asbestos-free COSID 120 brake lining is a rubber-bonded material. The binder makes it slightly flexible, so the lining can be easily adapted to different surface shapes and radii. The material does not contain metal components. It is suitable for gluing or riveting and is easy to machine. COSID 120 is gray in color, has a high and relatively constant friction coefficient, and excellent wear resistance.

Applications: used in hoist brakes, various industrial applications, in the form of various flat shapes, rings, and special shapes. The material can be used only in dry operation.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 131

COSID 131 is a flexible friction material offered as a friction sheet. The material concept is based on a rubber compound. It was developed specifically for applications requiring medium or high levels of dynamic friction. COSID 131 maintains a very stable level of friction throughout the designed temperature range.

Applications: industrial drum brakes compliant with DIN 15435, used in steel mills, cranes, hoists, belt conveyors, general material transport, and general industrial applications.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 132

COSID 132 is a rigid friction material offered as a friction sheet. The material concept is based on a rubber compound. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 132 is easy to process.

Applications: cranes, hoists, static applications.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 190

COSID 190 is a woven brake band with brass wire, impregnated with a special resin. It is characterized by high strength and good flexibility. Suitable for riveting and gluing. COSID 190 is brown, has a high friction coefficient under typical load conditions, and its wear resistance is excellent. It has been specially developed for applications requiring a medium level of dynamic friction.

Applications: Cranes, hoists, static applications, and general industrial use.

Form: flexible strips wound into rolls.

COSID 236

COSID 236 is a rigid friction material offered as a friction sheet. The material concept is based on a combination of rubber and resin compounds. It was specially developed for applications requiring a high level of dynamic friction. COSID 236 exhibits particularly high compressive strength.

Applications: industrial brakes and clutches with high pressure load, e.g. press clutches, drive shaft brakes, renewable energy.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 466

COSID 466 is a rigid friction material offered as a friction sheet. The material concept is based on a combination of rubber and resin compounds and contains metal fibers. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 466 has very good abrasive properties, also with respect to the mating material.

Applications: industrial drum brakes compliant with DIN 15435, used in steel mills, cranes, hoists, belt conveyors, and general material transport.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets or as a profiled drum brake lining.

COSID 516

COSID 516 is a rigid friction material offered as a friction sheet. The material concept is based on a resin compound with metal fibers. It was specially developed for applications requiring a medium or high level of dynamic friction. COSID 516 has very good abrasive properties, also with respect to the mating material.

Applications: standard industrial brake applications.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 600

COSID 600 is a rigid friction material offered as a friction sheet. The material concept is based on a combination of rubber and resin compounds and contains metal. It has been specially developed for applications requiring a very high level of static friction. In addition to static applications, COSID 600 is also able to perform dynamic emergency stops.

Applications: Holding brakes, high-performance clutches.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 904

COSID 904 is a rigid friction material offered as a friction sheet. The material concept is based on a rubber compound. It was developed specifically for applications requiring a low level of dynamic friction.

Applications: Forming and forging presses.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 907

COSID 907 is a rigid friction material offered as a friction sheet. The material concept is based on a rubber compound. It was specially developed for applications requiring a medium or high level of dynamic friction. COSID 907 has very high impact resistance.

Applications: forming and forging presses.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 909

COSID 909 is a rigid friction material offered as a friction sheet. The material concept is based on a combination of rubber and resin compounds. It has been specially developed for applications requiring a medium level of dynamic friction. COSID 909 has very high impact resistance.

Applications: forming and forging presses.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.

COSID 1203

COSID 1203 is a flexible friction material offered as a friction sheet. The material concept is based on a combination of rubber and resin compounds and contains metal. It was developed specifically for applications requiring a medium or high level of dynamic friction. COSID 1203 has very low sparking tendency.

Applications: mining equipment, wire winding machines.

Form: 400x500 mm sheets (size being phased out), 500x500mm and 420x600mm sheets.